As the electrification trend shifts society toward more electric aircraft, vehicles and industrial products, people will need more reliable power generation options. As a result, engineers need to perform an accurate fatigue analysis to ensure generator sets (gensets) can last years — even decades — with minor maintenance.

The frame that carries a genset, also known as a skid, is typically one of the first things to go. This isn’t too surprising as the skid must carry the weight of the genset and survive engine vibrations.

As a result, predicting the lifespan of a genset’s skid is one of the best ways to predict the lifespan of the genset itself. However, it can be challenging to get a strain history of the skid that is accurate enough for fatigue analysis.

To address this challenge, engineers from Cummins employed Wolf Star Technologies’ True-Load strain correlation models with structural analysis tools in ANSYS Mechanical.

Cummins Needs Accurate Stain Histories to Perform a Fatigue Analysis of a Genset

Since fatigue predictions are on a log-log scale, an error of 15% to 20% in the strain history could balloon into a 200% error in the life expectancy model of the genset’s skid.

This means that Cummins’ previous method to predict strain — using an experimental survey and accelerometers — wasn’t accurate enough for fatigue prediction applications.

True-Load, however, can use finite element analysis (FEA) models from Mechanical to determine the optimal placement of strain gauges on physical assets. It can then back calculate the asset’s loading.

Using this method, Cummins was able to improve the accuracy and speed of its strain history predictions by integrating True-Load into ANSYS SpaceClaim Direct Modeler and Mechanical.

How Cummins Predicted the Optimal Strain Gauge Locations to Perform a Fatigue Analysis

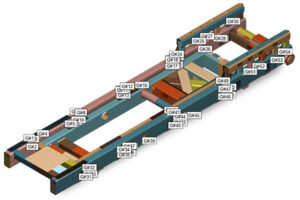

The first step was to use SpaceClaim to defeature the geometry of the skid. This process removed the gaps and faces that would have needlessly increased the elements within the mesh.

Next, Mechanical was used to perform a modal analysis on the genset’s skid.

The skid’s modal analysis discovered 24 modes of interest. These modes were input into True-Load to determine the best locations to place strain gauges.

Once the gauges are installed in these optimal locations, Cummins can obtain stress/strain data that is reliable enough to perform a fatigue analysis. This fatigue analysis will ensure that the electrification trend will continue with reliable power generation.

For more information about the ANSYS product range, please click here >>

This blog was originally posted on ANSYS’ website here.